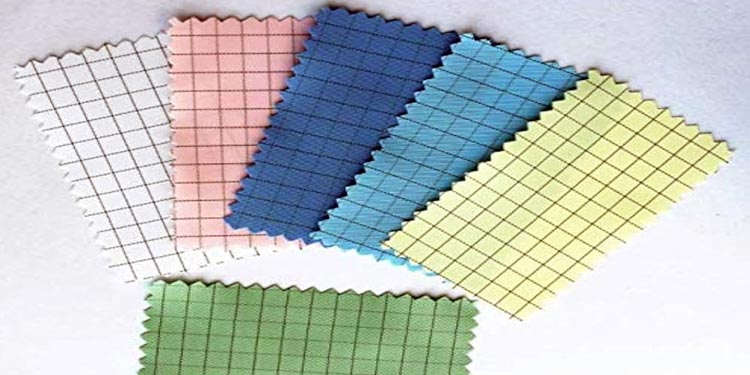

Anti Static Finish for Textile

Anti-Static Finish is a specialized textile treatment designed to reduce or eliminate the build-up of static electricity on fabric surfaces. Static charge occurs when fabrics rub against each other or other materials, especially in low-humidity environments, leading to uncomfortable clinging, dust attraction, and even small electric shocks. The anti-static finish works by increasing the fabric’s surface conductivity — usually through the application of chemical agents that attract and retain a thin layer of moisture or by incorporating conductive fibers.

This allows electrical charges to dissipate safely instead of accumulating. Fabrics treated with an anti-static finish remain comfortable to wear, resist dust and lint, and maintain a clean, smooth appearance. This finish is particularly important for workwear, uniforms, electronic industry garments, and upholstery fabrics, where static control is essential for safety and performance. In addition to improving wearer comfort, anti-static treatments can enhance fabric durability and contribute to higher product quality, especially when combined with other functional finishes such as flame retardant or water repellent coatings.

Anti-static finishes in textiles are chemical treatments applied to reduce or eliminate static electricity buildup, especially in synthetic fabrics. These finishes improve comfort, safety, and handling during production and wear.

Here’s a detailed overview of how anti-static finishes work and their importance:

Why Static Electricity Is a Problem in Textiles

- Synthetic fibers like polyester and nylon are hydrophobic and prone to static buildup.

- Friction during processing or wear causes electrostatic charges, leading to:

- Fabric clinging

- Dust attraction

- Electrical shocks

- Ballooning of yarns during spinning or weaving

Mechanism of Anti-Static Finishes

- Chemical treatments are applied to the fabric surface to increase conductivity or moisture retention.

- These finishes work by:

- Absorbing moisture to dissipate charges

- Creating conductive pathways using ionic or polymeric compounds

- Reducing surface resistivity to prevent charge accumulation

Types of Anti-Static Finishes

Sources:

Application Methods

- Padding: Fabric is passed through a bath containing anti-static agents.

- Spraying: Surface application for temporary effect.

- Exhaust method: Used during dyeing or finishing stages.

- Coating or lamination: For technical textiles needing long-term performance.

Benefits of Anti-Static Finishes

- Improved comfort and wearability

- Enhanced safety in flammable or electronic environments

- Better process efficiency in textile manufacturing

- Reduced dust and lint attraction

If you're working with synthetic fabrics or technical textiles, anti-static finishes are essential for performance and user experience. You can explore more technical details