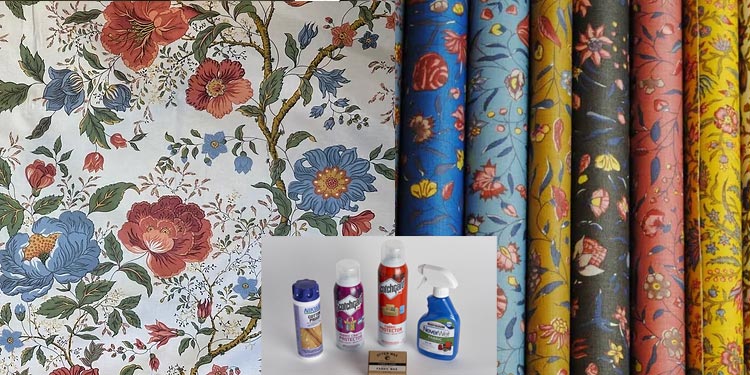

Stotch Guard Finish

Stotch Guard Finish is an advanced textile treatment and printing technique designed to provide fabrics with superior stain resistance, water repellency, and enhanced durability without compromising their natural look and feel. This technology involves applying specialized Scotchgard coatings or inks during or after the printing process, creating a protective barrier on the fabric surface that repels liquids, oils, and dirt. The treatment is compatible with a wide range of fabrics, including cotton, polyester, CVC blends, and synthetics, making it ideal for both fashion and functional textiles. In addition to offering protection against spills and stains, Stotch Guard Finish helps maintain vibrant colors and sharp print designs, even after repeated washing and exposure to outdoor conditions.

This makes it especially suitable for garments, upholstery, curtains, workwear, uniforms, and home décor textiles, where both aesthetic appeal and practical performance are essential. By integrating Scotchgard technology with modern textile printing methods such as screen printing, digital printing, or sublimation, manufacturers can deliver fabrics that combine style, comfort, and long-lasting protection, providing end-users with textiles that remain clean, durable, and visually striking over time.

Our Mission:

To provide exceptional printing services that combine creativity, technology, and sustainability — helping businesses communicate their message with impact and quality they can trust.

Why Choose Rotary Print:

-

Choosing Scotchgard protection for your printed fabrics and textiles ensures long-lasting durability, vibrant colors, and enhanced performance. While Scotchgard itself is not a printing medium, applying it after printing creates a protective barrier that repels liquids, resists stains, and prevents smudging, helping your designs maintain their original look and quality over time. This is especially valuable for screen-printed t-shirts, fabric banners, embroidered items, and textile art, where frequent handling or exposure to moisture could otherwise degrade the print. Scotchgard also preserves the softness, texture, and comfort of fabrics while extending the life of both everyday garments and specialty textile products. By choosing Scotchgard, you are investing in reliable protection, easy maintenance, and professional-quality results that keep your printed or decorative textiles looking fresh, vibrant, and durable for years.

Key Features of Rotary Printing

-

Continuous Printing Process

Rotary printing operates with a rotating cylindrical screen or plate, enabling a continuous flow of printing. This makes it perfect for producing long rolls of material efficiently and consistently.

-

High-Speed Production

Designed for mass production, rotary printing can handle large volumes in a shorter time compared to traditional printing methods — ideal for industries like textiles, packaging, and wallpaper manufacturing.

-

Consistent Print Quality

The rotating mechanism ensures uniform ink distribution across the entire surface, resulting in sharp, consistent, and high-quality prints from start to finish.

-

Versatility in Materials

Rotary printing is suitable for a wide range of substrates, including fabric, paper, plastic, film, and foil, making it adaptable across different industries.

-

Fine Detailing and Accurate Registration

Advanced rotary printing systems allow for precise color alignment and detailed designs, ensuring each print perfectly matches the intended artwork.

-

Automated and Efficient Operation

Most modern rotary presses are automated, improving accuracy, reducing human error, and saving both time and labor costs.

-

Variety of Inks and Colors

Compatible with multiple ink types — such as pigment, reactive, and acid inks — rotary printing allows for vibrant, long-lasting colors on various materials.

-

Reduced Waste and Downtime

Because of its continuous and automated nature, rotary printing minimizes material waste and machine stoppages, contributing to cost efficiency and sustainability.

-

Scalability and Flexibility

Whether for small batches or high-volume production, rotary printing systems can easily scale to meet different production needs without compromising quality.

-

Integration with Other Processes

Rotary printing can be combined with digital printing, coating, or finishing techniques for added design effects and enhanced durability.